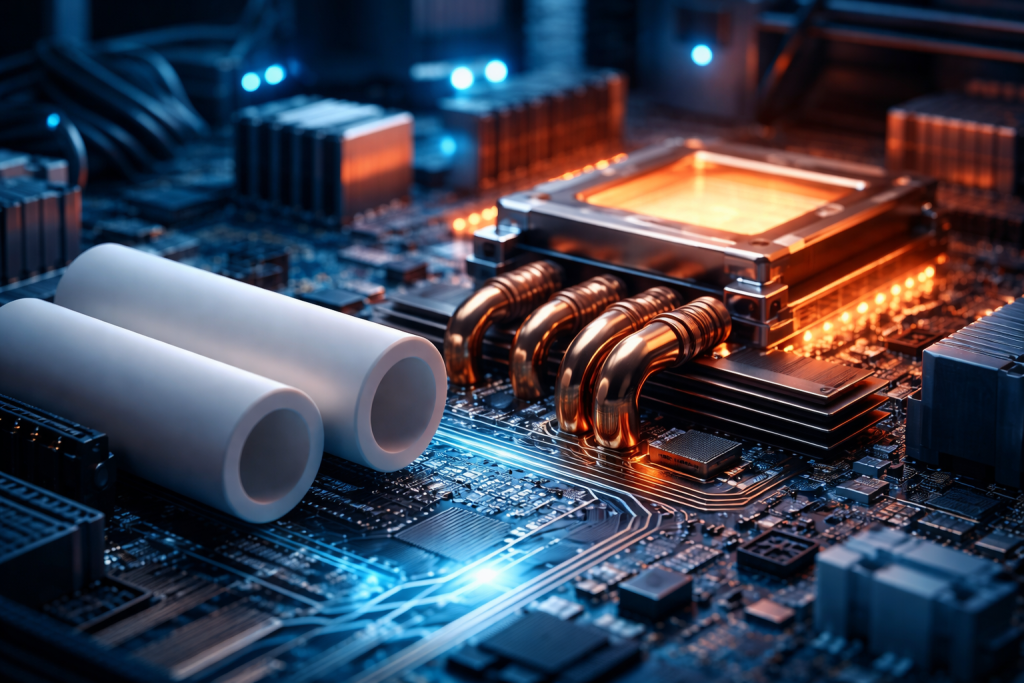

High-performance computing (HPC) hardware is often evaluated through short, intensive benchmark runs that highlight peak throughput. Yet in real deployments—data centers, automated test racks, and edge computing cabinets—systems are expected to operate continuously under thermal and mechanical stress. In these environments, sustained performance matters far more than momentary speed. The difference between a system that merely performs well in a benchmark and one that remains stable over months or years frequently comes down to materials.

As thermal loads increase with higher power densities, engineers are paying closer attention to how heat is generated, transferred, and contained throughout the system. Beyond processors and cooling algorithms, structural and insulating components play a decisive role. In industrial-grade assemblies, alumina tube systems used to maintain thermal stability in high-load industrial equipment are one example of how material selection can directly influence long-term operational reliability.

Peak Performance vs. Sustained Stability

Benchmarks are designed to push hardware to its limits over a short period. While useful for comparison, they do not fully reflect real operating conditions. Continuous workloads introduce thermal cycling, localized hotspots, and gradual material fatigue. Over time, even small fluctuations in temperature can affect alignment, electrical insulation, and signal consistency.

Sustained thermal stability ensures that components remain within safe operating limits without excessive drift. This is especially critical in environments where downtime is costly or unacceptable. Engineers increasingly recognize that achieving stable performance is not only a software or cooling challenge but also a materials engineering problem.

Thermal Challenges Inside Modern Hardware Systems

Modern computing hardware concentrates immense processing power into compact spaces. This density creates several thermal challenges:

- Localized heat accumulation around processors and power modules

- Thermal expansion mismatches between adjacent components

- Degradation of insulating materials under prolonged heat exposure

If unmanaged, these factors can lead to mechanical stress, electrical leakage, or premature failure. Traditional materials may perform adequately at moderate temperatures but lose dimensional stability or insulating strength as conditions intensify.

Why Material Choice Is a Reliability Factor

Materials define the physical boundaries within which hardware operates. Properties such as thermal conductivity, dielectric strength, and resistance to chemical or oxidative degradation determine how well a system tolerates heat over time. In demanding environments, materials must maintain their characteristics despite continuous exposure to elevated temperatures.

Advanced ceramics are often selected for such roles because they combine thermal resistance with mechanical rigidity and electrical insulation. Their ability to remain stable under harsh conditions makes them suitable for applications where metals or polymers would deform, corrode, or lose performance.

Controlling Heat Through Structural Design

Thermal management is not limited to heat sinks and airflow. Structural components can guide, isolate, or contain heat within defined pathways. Properly designed housings, supports, and insulating barriers prevent unwanted heat transfer to sensitive areas.

Ceramic-based structures are frequently used to separate high-temperature zones from electronics or measurement components. Their low thermal expansion and high melting points help preserve alignment and spacing, which is essential for precision hardware and test systems.

The Role of Testing and Validation

Before hardware is deployed at scale, it undergoes extensive validation to ensure reliability under expected operating conditions. Thermal testing, in particular, requires environments where temperature can be precisely controlled and repeated consistently.

In these contexts, high-purity alumina crucible components supporting controlled high-temperature testing environments are commonly used to evaluate material behavior, heat tolerance, and long-term stability. Such testing helps engineers predict how systems will respond to prolonged thermal stress and informs design decisions early in development.

Long-Term Effects of Thermal Cycling

Thermal cycling—the repeated heating and cooling of components—can be more damaging than constant high temperatures. Each cycle introduces expansion and contraction, which may lead to microcracks, loosening of interfaces, or gradual loss of insulation performance.

Materials chosen for critical components must therefore exhibit not only high temperature resistance but also fatigue endurance. Stable materials reduce maintenance requirements and extend service life, contributing to lower total cost of ownership for complex hardware systems.

From Data Centers to Industrial Computing

While HPC is often associated with large data centers, similar principles apply to industrial and edge computing. Control systems, automated inspection platforms, and monitoring devices frequently operate in environments with limited cooling and variable ambient temperatures.

In such cases, passive thermal stability becomes even more important. Materials that can inherently withstand heat without active intervention provide a margin of safety and simplify system design.

Designing for Reliability, Not Just Speed

As computing demands continue to grow, engineers are shifting focus from chasing peak benchmark numbers to designing systems that deliver consistent performance over time. This shift emphasizes durability, predictability, and resilience.

Material selection is a foundational part of this approach. By choosing materials that maintain structural and electrical integrity under thermal stress, designers can ensure that hardware performs as intended throughout its operational lifespan.

Conclusion

Thermal stability is a defining factor in the reliability of high-performance computing hardware. While software optimization and cooling strategies are essential, they cannot compensate for inadequate material choices. Structural and insulating materials form the backbone of any system designed for continuous operation.

By prioritizing materials that offer proven thermal resistance and dimensional stability, engineers can bridge the gap between impressive benchmark results and dependable real-world performance. In the evolving landscape of high-performance and industrial computing, materials are no longer a secondary consideration—they are a central element of system design.